Sheroz Earthworks for Beginners

Sheroz Earthworks for Beginners

Blog Article

Getting The Sheroz Earthworks To Work

Table of Contents7 Simple Techniques For Sheroz EarthworksFascination About Sheroz EarthworksTop Guidelines Of Sheroz EarthworksAn Unbiased View of Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.

For any type of earthwork service provider, it is vital to perform job with top quality, precision, and on routine. Making use of machine control in work devices allows maximizing the different stages in the earthwork procedure, from preparing to the maintenance phase - topcon laser level. The device control system helps the machine driver in attaining the target aircraft swiftly and quickly

The maker control system overviews the driver with centimeter accuracy. Remote support saves time and cash, as it minimizes downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Our system's parts are carefully created to hold up against the harsh conditions of building sites. Contrast of the exact same job executed making use of machine control versus the standard approach discloses that, on average, the standard approach calls for 50% more time to achieve the exact same task as the technology-assisted method.

Seems great, appropriate? Go into the Xsite device control system; it's here to provide you with a significant benefit when dealing with earthmoving machinery. Discover exactly how Xsite Maker Control can improve your performance and make sure job safety and security! We recognize that learning a new innovation might feel like a drag, but do not worry! Our pleasant and specialist regional support solutions have obtained you covered, guaranteeing that you can maintain functioning smarter without disturbances while on the task! Via remote assistance, your local Xsite supplier can provide guidance or troubleshooting without having to visit the website! What type of excavators does device control fit? Xsite Device Control systems can be installed to any type of excavator from mini excavators to big mining excavators.

Exactly how does machine control work? In 2D systems, the equipment is outfitted with calibrated inclination sensors. These sensors are placed on the pre-determined components of the equipment in excavators the sensor are usually placed to the framework, boom (or booms), miner arm and to the quick coupler - fj dynamics auto steer price. By utilizing the information received from these sensing units the system can compute the specific setting of the excavators pail pointer in relevance to a reference factor.

The system is very easy to find out the fundamentals can be instructed in under one hour of training. With Xsite you don't have to fret about discovering all the suggestions and trick at the same time. Additional training and guidelines are constantly readily available over remote support when needed. Contact your local Xsite supplier to learn more! Just how does the remote assistance work? A wireless net connection makes it feasible to establish a remote connection between the device control system and the service center.

All about Sheroz Earthworks

Xsite Maker Control systems sustain open conventional file styles, enabling seamless information circulation from one system to one more. Depending on your option of system (with or without positioning, i.e., 2D or 3D), your equipment is equipped with inclination sensing units, a controller device, and a display/operating panel.

Numerous software and hardware solutions exist to aid establish a machine's present setting on the earth and contrast it with a preferred layout surfaceand construction operators can do even more to additional hints take advantage of the advantages. Machine control is the usage of various positioning sensing units and a display screen to give the operator with a referral in between the setting of the bucket or blade and the target quality.

Depending upon the configuration, maker control systems can give the driver with a basic visual overview to container or blade placement, or can instantly relocate the blade to grade by speaking to the equipment's hydraulics - https://www.bitchute.com/channel/ZL5AmiD4YMwh. There are machine control systems readily available for practically any kind of maker: , dozers, excavators, dirt and asphalt compactors, scrapers, leaners, grating makers, and pavers

How Sheroz Earthworks can Save You Time, Stress, and Money.

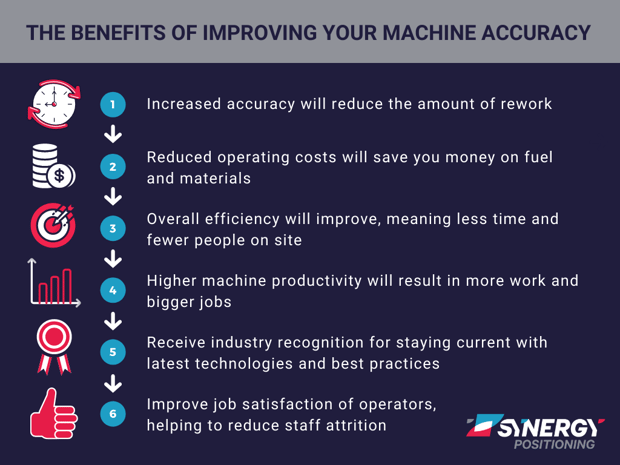

Device control can likewise assist enhance performance and reduce total prices. Construction tools without equipment control will come to be a point of the past and the advantages got from it will certainly be many.

Trimble machine control systems give a myriad of benefits to anyone who uses earthwork machinery and, at EarthCalc, we can offer you with 3D declare your equipment control-enable devices. Not exactly sure if maker control is worth the cost? Take into consideration the adhering to reasons you require to consider this alternative.

Making use of GPS lined up with your 3D style documents, these systems essentially ensure that you will eliminate or position the proper amount of material at the building website. On a lot of building websites, remodel is a common and aggravating fact, however with Trimble equipment control, you can remove the demand for rework.

Some Of Sheroz Earthworks

Frequently, with Trimble maker control, you can remove excess tools at a details job website. As an example, a job that may have called for the use of 3 or four pieces of excavating equipment now might require just two tools to accomplish the exact same job in much less time. This allows you to relocate your tools to an additional job site and take care of numerous jobs at once.

Report this page